Natural gas is a fossil fuel formed when layers of buried plants and animals are exposed to intense heat and pressure over thousands of years. The energy that the plants and animals originally obtained from the sun is stored in the form of carbon in natural gas. Natural gas is combusted to generate electricity, enabling this stored energy to be transformed into usable power. Natural gas is a nonrenewable resource because it cannot be replenished on a human time frame.

The natural gas power production process begins with the extraction of natural gas, continues with its treatment and transport to the power plants, and ends with its combustion in boilers and turbines to generate electricity.

Initially, wells are drilled into the ground to remove the natural gas. After the natural gas is extracted, it is treated at gas plants to remove impurities such as hydrogen sulfide, helium, carbon dioxide, hydrocarbons, and moisture. Pipelines then transport the natural gas from the gas plants to power plants.

Power plants use several methods to convert gas to electricity. One method is to burn the gas in a boiler to produce steam, which is then used by a steam turbine to generate electricity. A more common approach is to burn the gas in a combustion turbine to generate electricity.

Another technology, that is growing in popularity is to burn the natural gas in a combustion turbine and use the hot combustion turbine exhaust to make steam to drive a steam turbine. This technology is called "combined cycle" and achieves a higher efficiency by using the same fuel source twice.

Natural gas is a fossil fuel in liquid form that can be used as an energy source. When it's burned, it releases 25 percent fewer greenhouse gases and pollutants (sulfur, carbon, nitrogen) into the atmosphere than burning oil does. Natural gas is primarily methane gas (anywhere from 70 to 90 percent), but it also contains trace amounts of other usable gases, such as ethane, propane, butane and nitrogen.

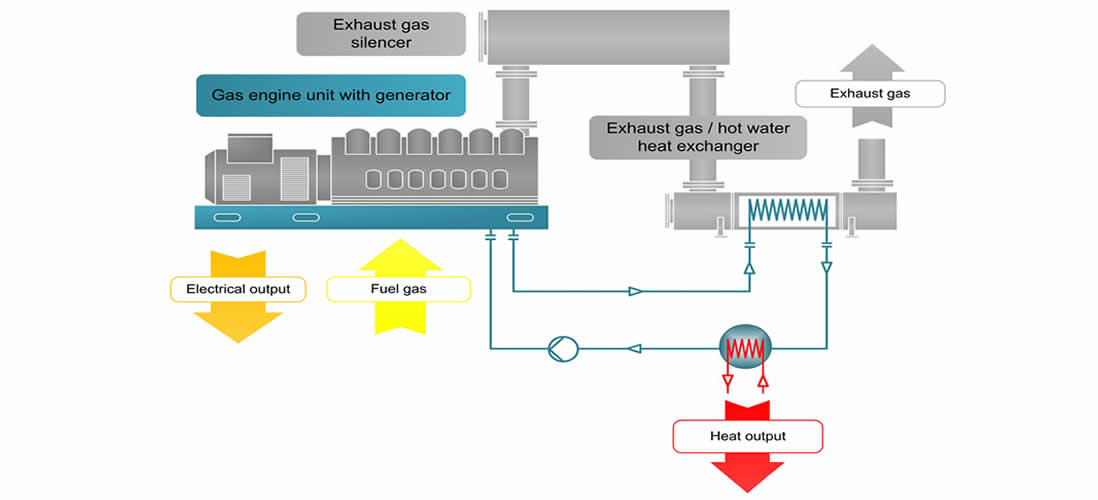

Cogeneration (cogen) through combined heat and power (CHP) is the simultaneous production of electricity with the recovery and utilization heat. Cogeneration is a highly efficient form of energy conversion and it can achieve primary energy savings of approximately 15-40% by compared to the separate purchase of electricity from the national electricity grid and a gas boiler for onsite heating. Combined heat and power plants are typically embedded close to the end user and therefore help reduce transportation and distribution losses, improving the overall performance of the electricity transmission and distribution network. For power users where security of supply is an important factor for their selection of power production equipment and gas is abundant, gas-based cogeneration systems are ideally suited as captive power plants (i.e. power plants located at site of use).

Contact us for more information